Electroplating in Brisbane, Queensland

These are the electroplating processes we do

Silver plating

Silver was one of the first metals to be electrodeposited commercially, and still holds pride of place as a finish for tableware, a purpose for which it is particularly suited by reason of its highly decorative appearance and resistance to attack by fruit juices and food stuffs.

Apart from decorative uses the electroplated metal plays an important role in industry. Its conductivity makes it ideal for electrical contacts, silver is also applied to high frequency components and wave guides to give a high surface conductivity where most of the current flows, thus giving a greater efficiency to these components. Other applications include items as diverse as light reflectors and engine bearings.

Copper plating

Copper because of its colour is one of the most decorative metals and can be polished to a high lustre or given an attractive brushed finish. The sensitivity of copper to tarnishing is used to good effect and chemical treatments can produce many artistic finishes from the oxidised copper colour to a pale green patina. All these finishes are then given a 2 Pac clear to ensure the desired effect is long lasting. Copper is also used on a very large scale for commercial use due to its rust presentation and conductivity properties.

Gold plating

Because of the presence of gold in the metallic state in nature it was one of the first metals to attract the attention of ancient man as evidenced by the discovery of early flint implements such as knives and daggers with gold handles. The art of gilding by the application of gold leaf and inlaying or “damascening” by hammering gold wire into the engraved pattern on a sword or other object of value has been practised for centuries. Apart also from its intrinsic value as a. Precious metal gold has been sought after throughout the ages for jewellery and for decoration, because of its rich and lasting colour. Indeed, our knowledge of many aspects of ancient ways of life have only come down to us because of the corrosion resistance of gold artefacts which have survived the years. Gold plating was practised by the ancient Egyptians, but this was only a thin hammered film on other metals. In the Middle Ages the process call fire gilding was used to ‘plate’ objects, in this method articles were coated with mercury/gold amalgam and subsequently heated to drive of the mercury. A layer of pure gold was left on the surface which could be burnished until bright. True electroplating of gold dates from the discovery of the couple cyanide of gold and potassium about the middle of the 19th century. As a decorative coating gold remains pre-eminent and some of its most important uses are in the jewellery, cutlery, and allied trades.

We plate in 18 carat gold and will generally plate in thickness’s ranging from 1-4um depending on your individual needs.

Nickel plating

Nickel is the most widely used electroplated deposit and it’s largest single application is as a decorative finish in which the nickel deposit is followed by bright chromium The finish generally known as “bright chrome”. However, nickel has its own mantle to sit on in terms of finish not just being used as an under coat to chrome. Bright nickel and brushed nickel are regularly used on decorative items from vintage cars and horse drawn buggies to door hardware and other trinkets around the home.

Chrome plating

The deposition of chromium is generally undertaken for one of two purposes: to provide a brilliant untarnishable finish, or to produce a abrasion resistant surface.

At Cooks Electroplating Pty Ltd, we specialise in decorative “bright Chrome plating”, which is a layer of nickel followed by a final deposit of chrome. We restore a vast majority of chrome plated items from car parts to household items, it is a very popular finish due to the fact it does not tarnish and requires only occasional washing with soap and water or wiping with a soft cloth to remove accumulation of dust and dirt from the surface.

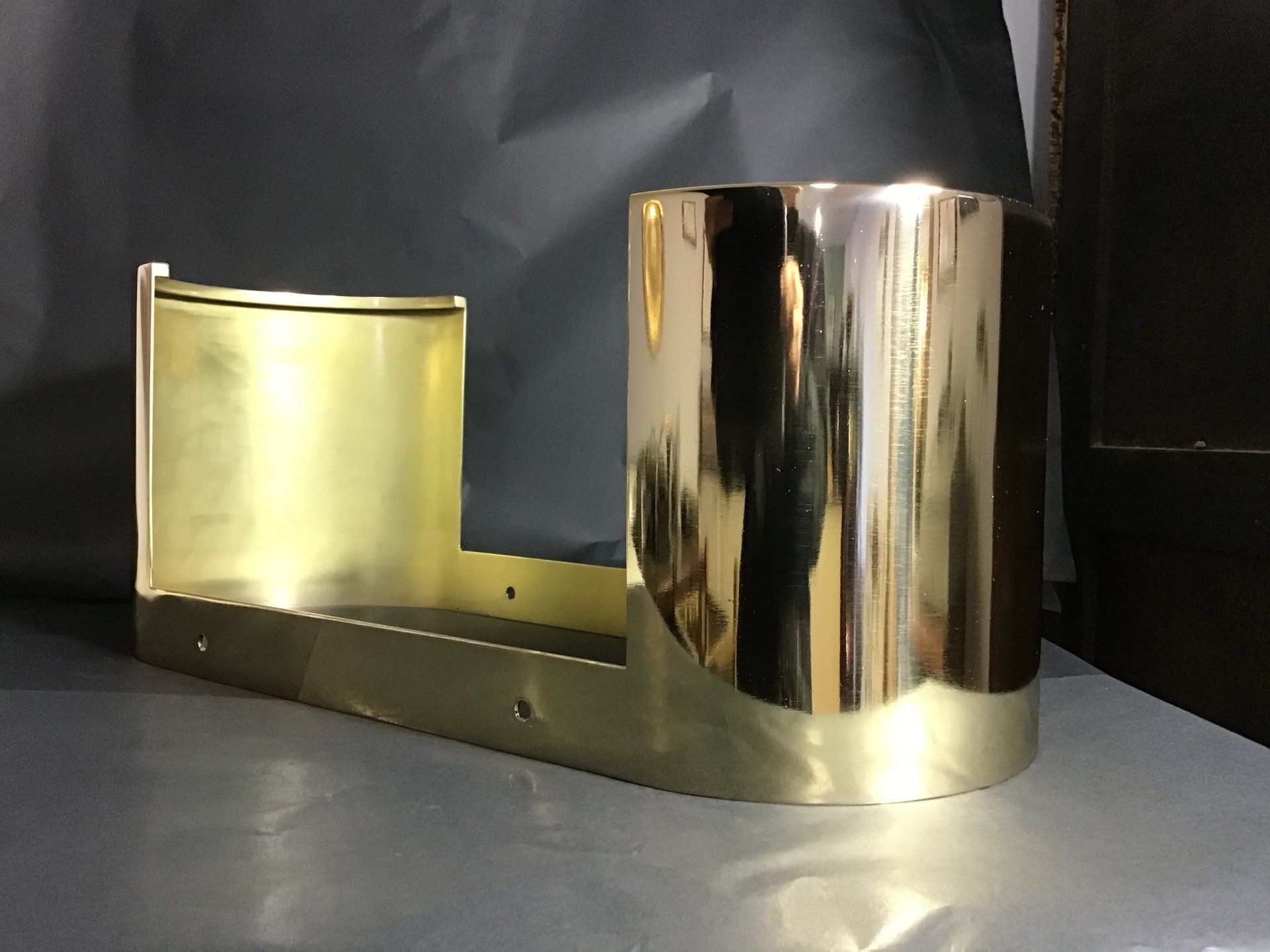

Brass plating

The principle application of brass plating is the production of decorative deposits, for decorative plating the alloy employed is generally 60 percent copper 40 percent zinc. The deposition of alloy deposits requires more care than the deposition of single metal deposits. Therefore, it is regularly acknowledged and accepted Across the industry that brass plating is the hardest discipline to get right and the hardest to get a premium finish. At Cooks Electroplating Pty Ltd we excel at delivering a premium Brass electroplated finish.

Tank Sizes

At Cooks Electroplating Pty Ltd we have a range of plating tanks for different applications, our copper nickel and chrome lines all boast 1.5-metre-long tanks with a plating depth of around 850mm.

Our brass and silver and gold line is slightly smaller with a plating capacity of 1.2 x .85 metres. Please speak to our knowledgeable office staff regarding your job and its size.

Barrel Electroplating

Barrel electroplating is a type of electroplating process used to deposit a layer of metal onto small parts or components. It is commonly used for mass production of small items such as screws, bolts, connectors, and other small metal parts. The process is called "barrel" electroplating because the parts are placed inside a rotating barrel-like container during the plating process.